A unique manufacturing system specially

designed for anticancer drugs.

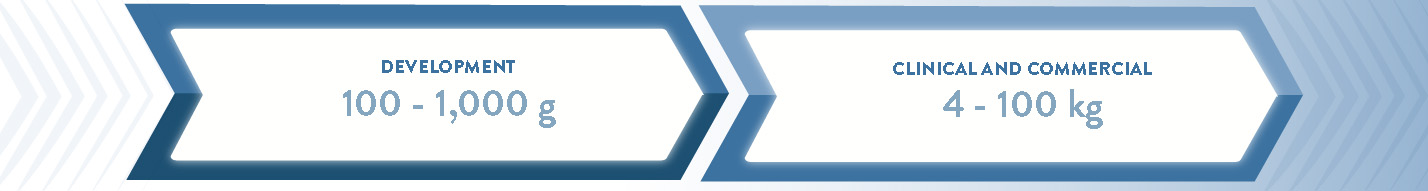

Our capabilities are designed to handle SMALL and LARGE MOLECULES, SOLVENT BASED FORMULATION and LIPID BASED FORMULATION for development, clinical and commercial supply.

equipped to handle Liquid and Lyophilized vials from 2 ml to 100 ml with filling lines designed to manufacture products with short holding time and minimize shear stress.

DEDICATED AREAS for THAWING

STATIC AND DINAMIC

TEMPERATURE CONTROL

DURING MANUFACTURING

CRYOGENIC LYOPHILIZERS

ENABLE A VERY ACCURATE AND EFFICIENT TEMPERATURE'S MANAGEMENT DURING EACH STEP

AUTOMATIC LOADING e ULOADING SYSTEM (ALUS)

DESIGNED FOR A RAPID INTRODUCING OF THE VIALS

THE LYO CHAMBER TO MINIMIZE PRODUCT'S EXPOSURE TO ROOM TEMPERATURE

100% CCIT BY FMS

VISUAL INSPECTION

MANUAL, SEMI-AUTOMATIC AND AUTOMATIC

SECONDARY PACKAGING available for Commercial supply and DEDICATED COLD STORAGE AREAS for DS, mAb, toxin and finish product (+2/+8°C; from -20°C up to -80°C) .

Our manufacturing equipment are designed to handle Cytotoxic and High Potent products under isolators for development, clinical and commercial supply.

DEDICATED HVAC SYSTEM

ORGANIC SOLVENT BASED FORMULATION

CLASSIFIED ENVIRONMENT

with controlled microbiological level

WIP

for isolators and equipment

For tablets, minitablets, capsules

WET GRANULATION

DRY GRANULATION

DRY BLENDING

FILM COATING

DEDUSTING

METAL CHECK

WEIGHT SORTING

PRIMARY PACKAGING

for Liquid Filled Hard Gelatine Capsules

PREPARATION OF OILY SOLUTIONS AND SUSPENSIONS

IN-LINE HOMOGENIZER

TEMPERATURE CONTROL DURING COMPOUNDING AND FILLING

IN-LINE BANDING

SEALING

100% LEAK TEST

VISUAL INSPECTION

PRIMARY PACKAGING

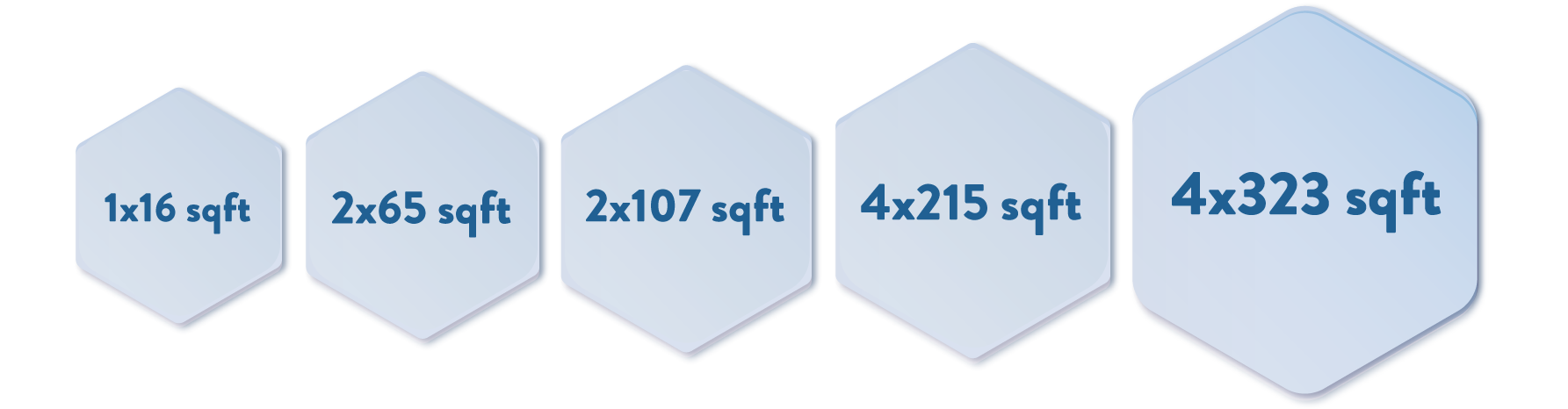

Batch size

from 1,000 to 250,000 units.